Two Technologies

for

Flow Measurement from Outside a Pipe |

Doppler and Transit Time are two very popular types of flow meter

for non-invasive measurement of flow in full pipes. We tend to

confuse these technologies because they are both ultrasonic and both

measure flow by using sensors clamped onto the outside of a pipe. In

the real world they actually work best in opposite applications.

Success in your installation depends on understanding the

differences and making the right choice.

|

|

Ultrasound is sound generated

above the human hearing range - above 20 kHz. Both

Doppler and Transit Time

flowmeter technologies are called "ultrasonic" because they

operate far above the frequencies or sound range that we can hear.

At the

heart of each ultrasonic transducer is a piezo-electric

crystal. They are glass disks about the size of a

coin. These crystals are polarized and expand or pulse

a minute amount when electrical energy is applied to the

surface electrodes. As it pulses the transducer emits an

ultrasonic beam approximately 5° wide at an angle designed

to efficiently pass through a pipe wall. The returning echo

(pressure pulse) impacts a second passive crystal and

creates electrical energy. This is the received signal in a

Doppler or Transit Time transducer. |

So far, both these piezo-electric

ultrasonic technologies seem much the same. No wonder the choice can

be confusing. But now let's look the differences.

Transit Time transducers typically operate in the 1-2 MHz

frequencies. Higher frequency designs are normally used in smaller

pipes and lower frequencies for large pipes up to several meters in

diameter. So operators must select transducer pairs/frequencies

according to the application. Doppler transducers usually operate at

640 kHz to 1 MHz frequencies and work on a wide range of pipe

diameters. |

|

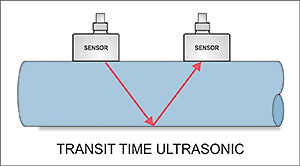

Transit Time flowmeters must

have a pair of transducers, each containing a piezo-electric

crystal. One transducer transmits sound while the other acts as a

receiver. |

|

As the name suggests, Transit Time flowmeters measure the time it

takes for an ultrasonic signal transmitted from one sensor, to cross

a pipe and be received by a second sensor. Upstream and downstream

time measurements are compared. With no flow, the transit time would

be equal in both directions. With flow, sound will travel faster in

the direction of flow and slower against the flow. Because the

ultrasonic signal must cross the pipe to a receiving transducer, the

fluid must not contain a significant concentration of bubbles or

solids. Otherwise the high frequency sound will be attenuated and

too weak to traverse the pipe. |

|

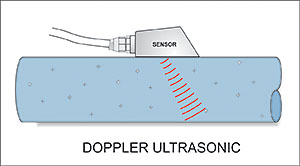

Doppler flowmeters manufactured by

Greyline Instruments use a single-head sensor design allowing fast,

simple mounting on the outside of pipes. The single-head transducer

includes both transmit and receive piezo-electric crystals in the

same housing. |

The Doppler effect was first documented

in 1842 by Christian Doppler, an Austrian physicist. We all hear

daily examples of the Doppler effect. It is the distinct tone change

from a passing train whistle or the exhaust from a race

car. We hear this tone change, or Doppler effect, only because we

are stationary and the sound transmitter - the train or the race car

- is in motion. Doppler flow meters use the principal that sound

waves will be returned to a transmitter at an altered frequency if

reflectors in the liquid are in motion. This frequency shift is in

direct proportion to the velocity of the liquid. It is precisely

measured by the instrument to calculate the flow rate. So the liquid

must contain gas bubbles or solids for the Doppler measurement to

work.

Two technologies,

one decision:

Doppler

flowmeters work best in dirty or aerated liquids like wastewater and

slurries. Transit Time

flowmeters work with clean liquids like water, oils and chemicals. Contact us for specific advice and information on selecting and applying these

technologies successfully in your application.

|

|

|